South Paris Switcher

Sunday, 3 March 2024

Monday, 13 February 2023

SP Auto Car

The Southern Pacific had Standard Steel car company build 500 single sheathed automobile cars for them in 1921. Built with 10'5" door openings, they were widened to either 12'0" or 12'6" in 1934. Some went to the T&NO while the rest stayed with the SP. The model is built from the excellent Speedwitch Media resin kit. The car is mostly stock, apart from a few brake component etchings, although I did scratch built new end ladders. Paint is Scalecoat Boxcar Red #2. Weathering is washes, dry brushing, acrylics and Pan Pastels. This car was delight to build.

Friday, 3 February 2023

Semet Solvay Tank Car

I started this Yarmouth Model Works Kit when I learned of my friend and fellow modeller Bill Welch's cancer diagnosis. Bill did a bunch of the Pattern work on this kit. While he was undergoing treatment in the hospital he asked for pictures of what others were working on to help pass the time. I sent a long a few progress shots, but Bill left us before I was finished.

This was a fun build and my first resin tank car. I spent a significant amount of time doing the brake plumbing on this car to match all the interesting features of the Prototype. I brought it to the Coco Breach RPM this past January, where another modeller complemented me on my effort by saying it was a really clean build. I was happy to hear this, as I strived to assemble this as if Bill had built it himself. Bill's work was always top notch.

Sunday, 29 January 2023

GTW Automobile Car Part 3

Well it's been almost three years since I last updated the progress on my GTW Automobile car. If you missed the first 2 blog entries, here are the links.

I've worked on many other projects over this time, but this car sat painted on the shelf waiting for me to decal and weather it.

Vallejo Fire Red was used for CN Freight Car Red, its a nice Oxide Red. I used Black Cat Publishing decals and NSC chalk marks. Weathering started with a Neutral Grey Filter, followed by oils put on with a makeup sponge to simulate rust specks. Then a liberal coating of various shades of Pan Pastels were applied. Between each step a flat coat was used, to seal each layer of weathering.

I took ten pictures using the focus bracketing feature of my camera and then stacked the images in Photoshop.

My new years resolution is to finish one project before I start a new one!

Thursday, 28 July 2022

Fleet Additions

Over the last two plus years, I've managed to build some rolling stock for my own layout. It's not all Hindsight Virtual RPM planning - as the current state of the blog would attest.

I was going at a clip of one car per month for a while and then things slowed down after National Scale Car acquired the Speedwitch Media line of decals. The captions give a bit more detail on the cars. The photos were all taken with my new camera and photo booth. Then focus stacked in photoshop. More on the Camera etc later but for now enjoy the photos..

|

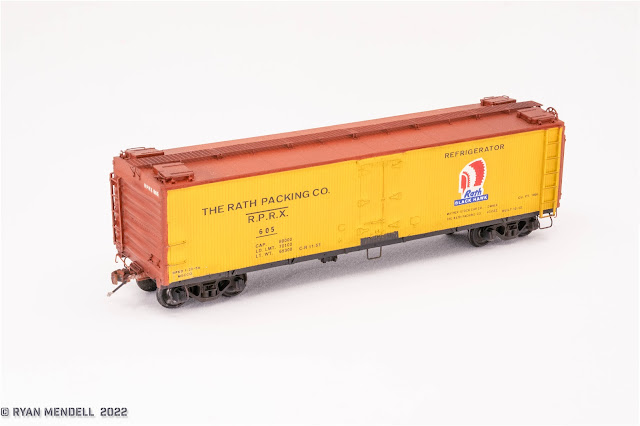

| Sunshine Rath Meet Reefer |

|

| National Scale Car Rock Island Mini Kit |

|

| Speedwitch Media Pere Marquettte Single sheathed Auto Car |

|

| Rapido Trains NP double sheathed box car kit, started out as an undec with a few changes to better represent a car that had the side to end straps added. |

|

| Resin Car Works GN 1937 double sheathed boxcar. |

|

| Speedwitch Media CN Fowler boxcar |

|

| National Scale Car CMO mini kit. |

|

| National Scale Car B&O M55A Boxcar mini kit |

|

| National Scale Car B&O M55 Boxcar mini kit |